Learn how to calculate cycle time with a simple formula to spot bottlenecks, optimize workflows, and deliver value faster - real-world examples included.

Do less, be more with Fluidwave

Fluidwave combines smart task prioritization with an assistant marketplace — AI and human help, all in one productivity app.

November 1, 2025 (3d ago)

How to calculate cycle time: boost efficiency now

Learn how to calculate cycle time with a simple formula to spot bottlenecks, optimize workflows, and deliver value faster - real-world examples included.

← Back to blog

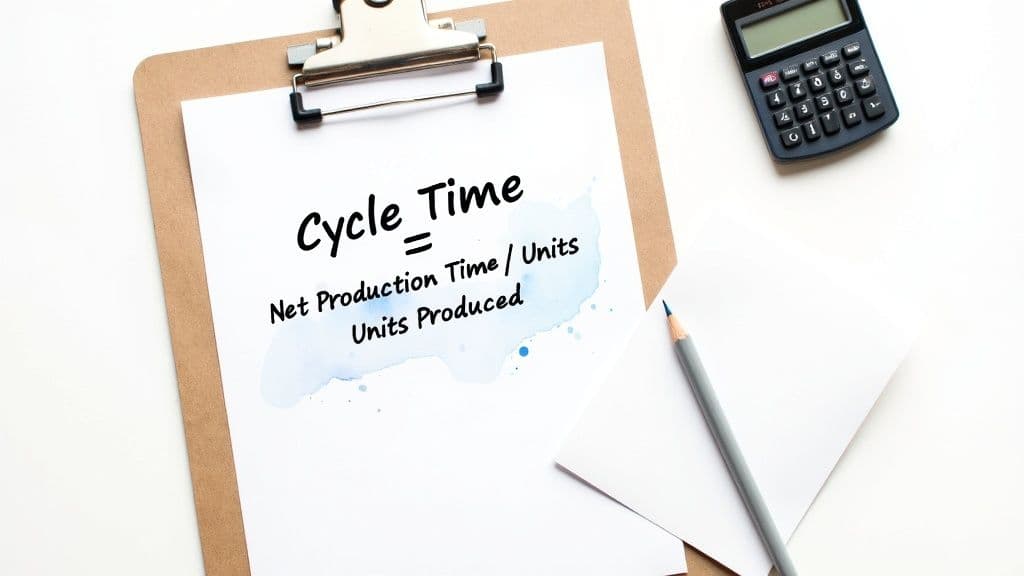

The simplest way to calculate cycle time** is by dividing your Net Production Time by the Number of Units Produced. This simple formula gives you the average time it takes your team to finish one piece of work, offering a clean, powerful snapshot of your production speed.

What Does Cycle Time Actually Tell You?

Before you get lost in the numbers, let's pin down what cycle time really is—and just as importantly, what it isn't. Think of it as the total time your team is actively working on a task. The clock starts the moment someone actually begins the work and stops the second it's ready for delivery or the next stage. It’s the "hands-on" part of your entire process.

This one metric can be a game-changer. It helps you spot hidden bottlenecks and makes your team's output way more predictable. If your cycle times are consistently high or all over the place for similar tasks, that's a huge red flag. It’s a clear sign that something in your workflow is causing friction and needs a closer look.

Getting Your Metrics Straight: Cycle Time, Lead Time, and Takt Time

To use this data well, you have to untangle cycle time from other metrics that often get tossed into the same bucket. I've seen countless teams track numbers without really getting what they're for, which always leads to well-intentioned but misguided "improvement" efforts.

Let's clear up the confusion between these three common metrics. Each tells a different piece of your story.

Cycle Time vs. Lead Time vs. Takt Time: A Quick Comparison

| Metric | What It Measures | Starts When... | Ends When... |

|---|---|---|---|

| Cycle Time | The time spent actively working on a task. | A team member begins active work on an item. | That specific piece of work is finished. |

| Lead Time | The total time a customer waits for a request. | A customer or stakeholder makes a request. | The final product or service is delivered. |

| Takt Time | The pace needed to meet customer demand. | (Not a measurement) | (Not a measurement) |

Knowing the difference is key. It makes sure you're focusing your efforts in the right place, rather than spinning your wheels on a part of the process that isn't the real problem.

Key Takeaway: Understanding the difference between these metrics is the first real step toward using data to make meaningful changes. Focusing on the wrong one can lead you to optimize the wrong parts of your workflow, wasting valuable time and resources.

For instance, trying to shorten your cycle time won't help if the biggest delay is the weeks a task spends sitting in a backlog before anyone even starts it—that's a lead time problem. Differentiating these lets you apply effort where it'll actually make a difference.

Tracking these core figures is fundamental to process improvement. To go deeper, you can explore other essential project tracking metrics in our detailed guide.

The Simple Formula for Cycle Time Calculation

Alright, let's get into the nuts and bolts. The formula to calculate cycle time looks simple enough, but the real magic is in knowing what the numbers actually mean.

Cycle Time = Net Production Time / Number of Units Produced

The most common mistake I see teams make is with the Net Production Time. This isn't just the total hours in a workday. It's the actual, hands-on time your team is actively producing something of value.

You have to be disciplined about excluding scheduled lunch breaks, company-wide meetings, or any unplanned downtime. If you leave that time in, you'll artificially inflate your cycle time and completely miss what your data is trying to tell you.

Defining Your Start and End Points

Before you even touch a calculator, your team needs to agree on one thing: when does the clock really start and stop for a task? If you don't nail this down, your measurements will be all over the place.

- Start Point: Does work begin the moment a task is created, or when someone actually picks it up and starts working on it? For most teams, tracking from the "active work" start time gives you a much more accurate picture of your process efficiency.

- End Point: Is a task "done" when the code is committed, or only after it passes QA and is fully deployed?

You have to get everyone in a room and agree on these definitions before you start tracking. Without this alignment, you're comparing apples to oranges, and any trends you spot will be useless. Trust me, this simple step saves you from massive headaches down the road.

Once you have these definitions locked in, using the formula becomes much more powerful. Let's walk through a couple of real-world scenarios to see how this plays out.

Practical Calculation Examples

Seeing the formula in action makes it all click. Here are two different examples—one from a factory floor and another from a software team—to show you just how versatile this metric is.

Scenario 1: A Busy Manufacturing Line

Imagine a small factory that assembles custom widgets. In a single 8-hour shift (480 minutes), the team takes a 30-minute lunch break. They also had to shut down a machine for 15 minutes to fix a jam.

- Total Shift Time: 480 minutes

- Non-Productive Time: 30 minutes (lunch) + 15 minutes (downtime) = 45 minutes

- Net Production Time: 480 minutes - 45 minutes = 435 minutes

- Units Produced: In that time, they assembled 145 widgets.

Now, we just plug those numbers into our formula:

Cycle Time = 435 minutes / 145 widgets = 3 minutes per widget

This tells the operations manager that when the line is running, a new widget is completed every three minutes. That's a solid, actionable piece of data.

Scenario 2: A Software Development Team

Let's switch gears. A software team is working on shipping a batch of 5 new features during a two-week sprint.

- Net Production Time: The team logs its active time spent on coding, testing, and code reviews. For these 5 features, that time adds up to 64 hours.

- Number of Units: 5 completed features.

Let's run the calculation:

Cycle Time = 64 hours / 5 features = 12.8 hours per feature

This gives the project manager a fantastic baseline. They now know it takes, on average, a little over a day and a half of focused work to get a single feature from start to finish.

Using Technology to Measure Cycle Time Accurately

Sure, you can start with a spreadsheet and a stopwatch, but that manual approach will only get you so far. To get the kind of precise, actionable data that actually drives improvement, you need to bring in modern tools. Relying on manual entries almost always leads to human error, inconsistencies, and a frustrating lag between something happening and you actually getting the data to analyze it.

This is where automated tools really shine. They don't just measure cycle time; they give you a continuous, real-time stream of data for a much clearer, more honest picture of your team's efficiency. Automation strips away the guesswork and subjective reporting that often muddies the waters with manual tracking.

The Power of Automation and AI

Modern project management software and specialized analytics platforms are built to handle this automatically. By hooking directly into your workflow, these systems can log the start and end times for each task as it moves from one stage to the next. That means you get precise, error-free data without asking your team to do a single extra thing.

Think about it: when a card moves from "In Progress" to "In Review" on a digital Kanban board, a timestamp is captured instantly. That level of automation is essential for anyone serious about optimizing their workflow. If your team is already using a visual system to manage work, you might want to explore some Kanban best practices to see how you can refine your process even further.

But it gets even better. AI-driven tools are taking this a huge step forward. They don't just report on what happened last week; they actively help you find opportunities to improve.

By sifting through massive amounts of historical data, AI algorithms can pick up on subtle patterns and connections a person would probably miss. This could be anything from flagging that a specific team member’s work consistently gets bogged down in the review phase to predicting which types of tasks are most likely to blow past their average cycle time.

Real-Time Insights from IoT

For those in manufacturing or physical production, the Internet of Things (IoT) brings an incredible new level of precision to the table. Smart sensors placed on machinery or along a production line can track every single step of a process automatically, completely eliminating the need for manual data entry and providing a constant flow of information.

The impact here is massive. For example, AI-driven process optimization has been shown to slash cycle times by around 20% in injection molding. This trend is only accelerating; it's predicted that by 2025, about 70% of global manufacturers will be using IoT for real-time monitoring, enabling precise cycle time measurement and immediate adjustments.

At the end of the day, whether it’s through project management software in an office or IoT sensors on a factory floor, technology gives you the data you need to be truly proactive. It helps you move from just knowing your cycle time to deeply understanding the forces that shape it, empowering you to make smarter, faster decisions.

Common Mistakes to Avoid in Your Calculations

Knowing how to calculate cycle time is a great first step, but the real challenge is doing it accurately in the wild. I've seen even the most well-intentioned teams make a few common mistakes that can completely skew their data. Getting this right is critical—bad data leads to bad decisions.

One of the most frequent errors is having a moving target for your start and end points. Maybe this week, a task is "done" once the code is committed. But next week, it's only "done" after it passes QA. This kind of inconsistency makes it impossible to compare apples to apples over time, so you'll never spot real trends.

You're basically measuring different processes but calling them the same thing. Before you track a single task, get everyone on the same page and hammer out a crystal-clear, shared definition of what "start" and "done" actually mean for your team.

Confusing Active Work with Total Time

Another classic pitfall is letting idle time sneak into your Net Production Time. This metric should only reflect the time your team is actively working on a task. Including non-productive time will inflate your cycle time and hide how efficient your team truly is.

To get clean, actionable data, you have to be disciplined about what you measure.

- Exclude Scheduled Breaks: Lunch and other planned breaks are not part of the active work.

- Remove Queue Time: The time a task spends waiting for approval or just sitting in a queue is part of lead time, not cycle time.

- Account for Downtime: Unplanned system outages or machine maintenance shouldn't count against your team's active work time.

The goal isn't to game the numbers; it's to get an honest look at your active work phase. Pumping up your cycle time by including idle periods just masks the very bottlenecks you’re trying to uncover.

Without making these distinctions, you'll get a distorted view. You might think your team is slow when the real holdup is a sluggish approval process.

Focusing on the Wrong Metric

Finally, a surprisingly common mistake is optimizing for the wrong thing altogether. As we've talked about, cycle time and lead time measure two very different aspects of your workflow. Cycle time is all about your internal process speed, while lead time is the full customer experience, from request to delivery.

Imagine your team works incredibly hard to shave a full day off its cycle time for a new feature. That feels like a huge win! But if that same feature request sat in a backlog for three weeks before anyone even started it, the customer's experience hasn't changed one bit. Their lead time is still massive.

Before you start optimizing, be clear on what you want to achieve. If you want to make your internal workflow more efficient, by all means, focus on cycle time. But if your goal is to deliver value to customers faster, you absolutely have to look at the entire lead time. Zeroing in on the wrong metric can cause you to fix a part of the process that was never the real problem.

Turning Cycle Time Data Into Real Improvements

Okay, so you've managed to calculate cycle time. That’s a great start, but the real work is just beginning. The goal isn't just to get a number—it’s to shrink that number and make your delivery times more predictable. This is where your data stops being a simple metric and becomes a powerful tool for change.

The first thing to do is dig into your results and find the story behind the numbers. Where are the delays really coming from? A great way to do this is by breaking down your entire workflow into distinct stages—like "Drafting," "Review," and "Final Approval"—and then measuring the cycle time for each part. This simple act often uncovers some surprising holdups.

Pinpointing Your Bottlenecks

In my experience, a common culprit for a bloated cycle time is the handoff between teams or individuals. It’s a classic scenario: a task might only require a few hours of actual, hands-on work, but it ends up sitting in someone's queue for days waiting for the next person to pick it up. Is the "review" stage taking longer than the work itself? That's a textbook bottleneck that grinds your entire process to a halt.

Once you spot these problem areas, you can start asking the right questions.

- Is there a skills gap? Does one particular stage consistently drag on because the team is missing specific expertise or the right tools?

- Is the process too complicated? Are there too many unnecessary approval steps or bureaucratic hurdles that don't add any real value?

- Is communication breaking down? Do tasks stall out because of vague requirements or slow feedback loops?

Pinpointing the exact stage that causes delays is crucial. Without this specificity, any attempt at improvement is just a shot in the dark. You can't fix a problem you haven't clearly identified.

Armed with this information, you can stop just observing the problem and start actively solving it. The data gives you the hard evidence you need to have productive, fact-based conversations about process improvements instead of just relying on gut feelings. It’s not about pointing fingers; it’s about making the whole system work better for everyone.

Implementing Practical Optimizations

Once you know where your process is getting stuck, you can roll out practical strategies to get things moving again. The right solution will always depend on the specific bottleneck you’ve found, but a few common and highly effective approaches can make a big difference.

Here are a few strategies I've seen work time and again:

- Automate Manual Tasks: Hunt for those repetitive, low-value jobs that can be automated. This could be anything from sending out status update emails to automatically moving a task to the next stage once a checklist is complete. Every minute you save here chips away at your cycle time.

- Streamline Approval Processes: If approvals are your bottleneck, simplify the chain of command. Can you get by with fewer approvers? Can you set clear SLAs (Service Level Agreements) for how quickly feedback needs to be provided?

- Improve Team Communication: Delays are often just a symptom of poor communication. Implementing daily stand-ups, writing clearer task descriptions, or creating dedicated Slack channels for projects can make handoffs dramatically faster.

Once you have a solid grasp on your cycle time data, exploring even more optimization tactics can pay off big time. For instance, you can dive into proven strategies to reduce cycle time specifically for your development workflow.

Ultimately, making cycle time a core KPI helps build a culture of continuous improvement. It gives your team a shared, concrete goal to rally around. As you implement changes and everyone sees the numbers go down, it creates a powerful feedback loop that motivates the whole team to keep refining the process. This approach is a cornerstone when you want to learn how to measure operational efficiency across your entire organization.

Common Questions About Cycle Time

We've walked through how to calculate cycle time, but a few questions almost always come up when teams first start using this metric. Let's dig into some of the most frequent ones to clear up any confusion.

Getting these details right is key. After all, consistent and accurate measurement is the only way to make real, sustainable improvements to your process.

What's the Difference Between Cycle Time and Takt Time?

This is a classic, and for good reason. It's easy to mix them up, but they tell you two very different things. The simplest way I've found to remember it is that cycle time is what you're doing, while takt time is what you need to do.

- Cycle Time: This is a measure of your current reality. It tells you how long it actually takes to get one unit of work from "in progress" to "done." It’s descriptive.

- Takt Time: This is a target calculated based on customer demand. It defines the pace you need to maintain to keep customers happy. It’s prescriptive.

Imagine your team's cycle time for a feature is three hours. But, to meet your launch deadline, you need to be shipping one every two hours—that's your takt time. Straight away, you know you have a capacity problem and are falling behind.

Should We Include Rework and Bug Fixes in Cycle Time?

This is a great question, and the answer really depends on what story you want the data to tell you.

For a pure measure of your core process efficiency, you could just track the "first-pass" time—how long it takes to complete a task correctly on the first try. This gives you a clean baseline for your workflow's speed.

However, if you want a true picture of the cost of poor quality, then absolutely include the time spent on rework and bug fixes. This reveals the hidden factory of effort that's dragging your team down.

A good practice is to track both. If you see a growing gap between your initial cycle time and your total cycle time (with rework), that’s a massive red flag. It tells you to focus on quality at the source, not just on working faster.

How Often Should We Measure Our Cycle Time?

There’s no magic number here; the right frequency depends on the rhythm of your work. The most important thing is to be consistent.

For a fast-moving agile software team, checking in weekly or even daily can help you spot and squash issues before they snowball. For teams working on longer, more complex projects, a monthly or quarterly review might be plenty to identify meaningful trends.

The goal is to pick a schedule and stick to it. Regular measurement turns anecdotes into data, allowing you to see patterns and make smart decisions before small delays become major roadblocks.

Ready to stop guessing and start optimizing? Fluidwave uses AI-driven automation and intelligent task management to give you a crystal-clear view of your team's cycle time. Take control of your workflow, eliminate bottlenecks, and deliver work faster than ever. Get started with Fluidwave today.

Do less, be more with Fluidwave

Fluidwave combines smart task prioritization with an assistant marketplace — AI and human help, all in one productivity app.